Overlay to stamp concrete on existing supports

How to use ?

1) Preparing surfaces

A stamped overlay will be durable and easy to maintain if applied properly. In order for the overlay to adhere successfully, you'll need to prepare the existing surface. The surface must be resistant, clean, hard without cracks. Remove all dust and other substances of old coating who could damage the grip of the product (paint, oil, grease, fluorescence, GLU, sealers...)

If you have some little cracks, you can repair it with an Epoxy Resin and insert a fiber mesh into this primer.

Warning : The treatment of the support is the key of your realization. Before applying the Masters Stamp Overlay, the support must be perfectly clean and you must apply the right bonding agent according to the support. Use only the bonding agents or Masters Prim Quartz.

2) Application

To prepare the mix, take a special bucket for mixing and put first 5 liters water.

Then, add gradually all the powder Masters Stamp Overlay (already coloured) contained in the bucket. Mix with a professional mixer with a slow speed (<600rpm) during 2 minutes. Once mixed, apply the product with a trowel and if necessary, adjust the thicknesses with a gauge rake. You must have a minimum of 1cm for light stamps like skins or textures, and 2 cm for classics stamps more structured. Once the product in place, smooth carefully with a trowel to have a perfect finish.

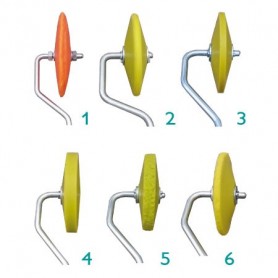

Wait until its start to set, and sprinkle the powder release agent or liquid agent release. Then stamp the surface with th select stamps

3) Protection

Apply one coat of sealer (water based or solvent based) after 48 hour drying and a second coat after 28 days.

- Masters Ecolex Sealer for water based

- Masters Outside Sealer for solvent based

- Form

- Powder

- Compositions

- Mix of cement and quartz aggregates

- Coverage

- One bag for 2sqm with 1cm thicknessOne bag for 1sqm with 2cm thickness

- VOC's

- None

- Colour

- 23 colors

- Shelf life

- 12 months

- Packaging

- Bag of 25kg

- Hardness

- 7/8 (Mohs scale)

- Granulometry

- 0,2 / 0,3 mm

- Density

- 2

- Compression resistance

- 75 Mpa